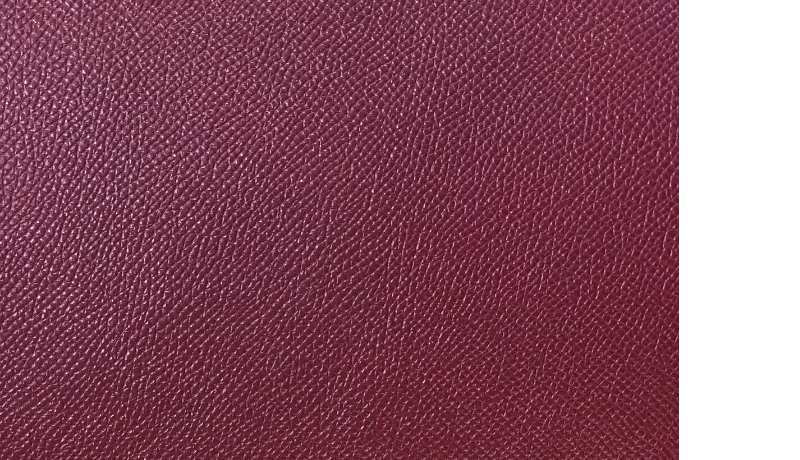

Superior has long been committed to a production that’s sustainable in every aspect. For this reason, we have been looking into practices that reduce the use of chrome without compromising the final result.

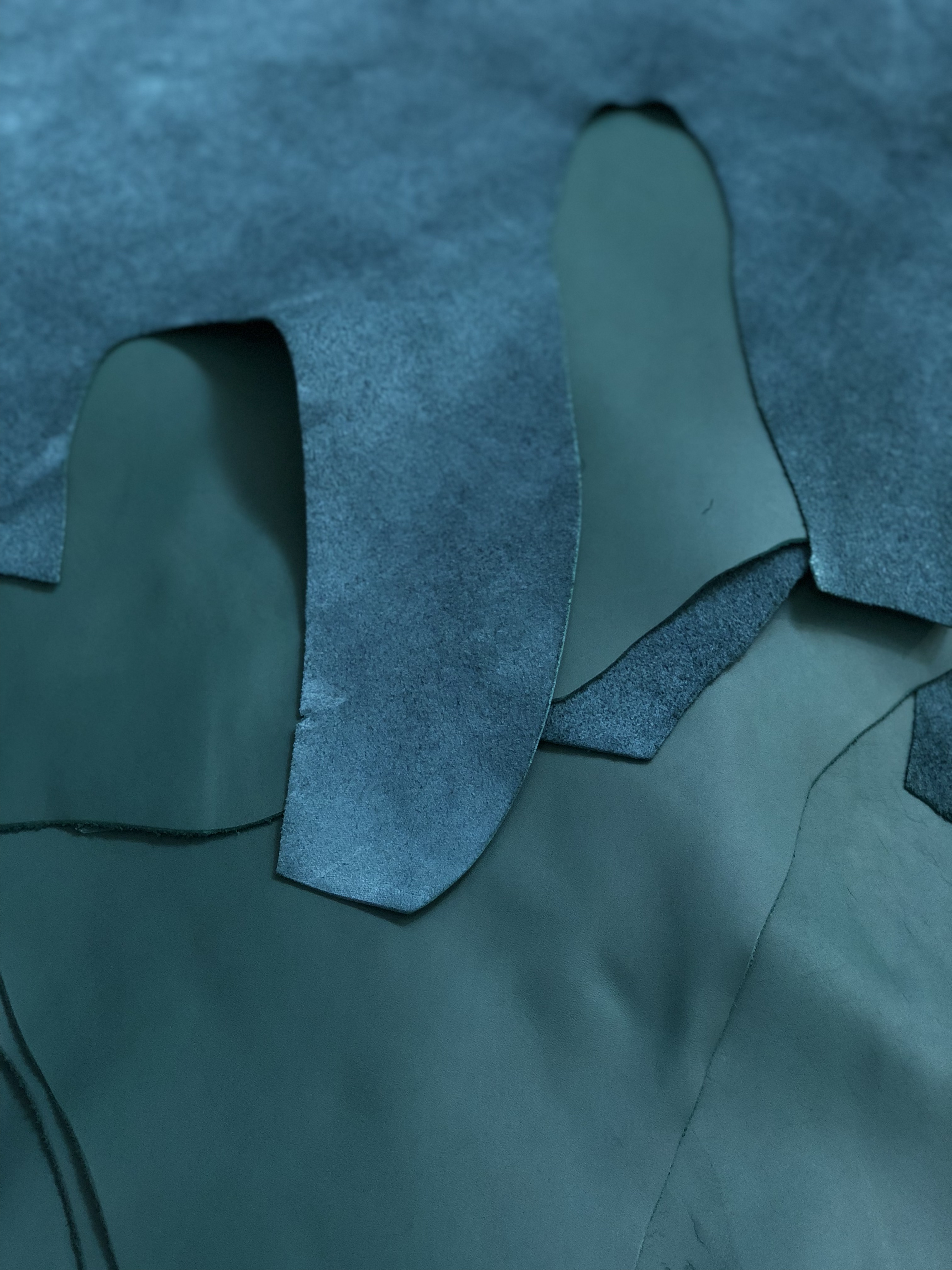

Chrome tanning is the process that infuses the leather with specific characteristics, both organoleptic and physical. To date, it remains the most widely used process in tanning, in fact, it is quite difficult that any other system yields the same results.

The chrome used in tanning is a chemical element that must be handled with the utmost caution. However, we’ve worked with it for years and we know how to control it, not only at the tannery but also at the extraction and purification stages.

Superior has committed to being fully sustainable and this implies a thorough analysis of all the chemicals used in tanning. Thanks to the support and commitment of our technicians we are working on 4 key focus areas:

- The recipes. We use chemical products, chrome in particular, that are easily absorbed by the leather.

- The process. We maintain a pH and temperatures that improve the binding of the chrome

- inside the leather.

- Innovation. During the ‘wet blue’ dye, we are experimenting with the use of ultrasounds to optimize the permeation of chrome into the leather.

- Recycling. We are studying the possibility of reusing waste from tanning.

It’s only by moving on all these fronts, and not just one, that we will make a difference. Our aim is to use less chrome for the same result when tanning, pre-tanning or retanning wet blue. The attention to recipes, process, innovation, and reuse not only allows us to reduce the consumption of chemical products but also the consumption of water and methane gas to produce hot water and steam.

Thanks to these studies, we are now able to maintain the characteristics of our leather, guaranteeing a high-quality result. Nevertheless, our technicians are already at work to study new processes in order to produce leathers with low chromium content. To innovate in an energy-saving and sustainable way.