Rooted in Tradition. Focused on the Future.

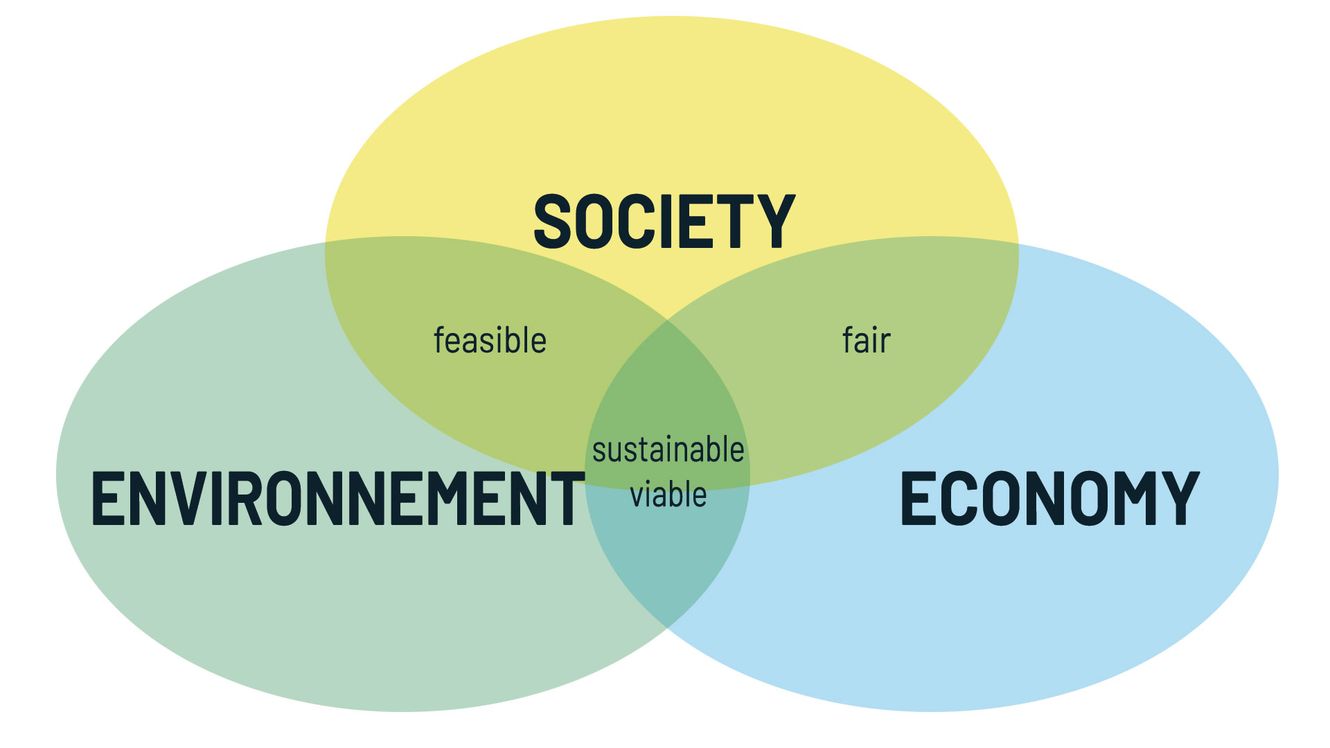

Environmental, economic and social sustainability: this is the direction Superior is taking today. After meticulous assessments and evaluations of past work, we identified what needed to improve and put the wheels in motion.

We focused in particular on:

Compliance with environmental and safety laws

Safety all around, final consumer included

Constant monitoring of economic, social and environmental impact

Research and best practice