Tanning, re-tanning and dyeing are the fundamental stages of “wet” leather processing, necessary to give the product some of its final characteristics such as softness, resistance and color.

The processing of the hides is a long process that involves many steps, some determined by the final effect we want to achieve. First, we must remember that leather is an organic material and must follow precise conservation protocols so that it can be processed and transformed into the finished product we all are accustomed to.

Currently, the Superior tannery is collaborating with the Scuola Normale Superiore of Pisa to make the “wet” phase of leather processing more sustainable. The studies carried out have the aim to increase the absorption capacity of the skin and to reduce the time, energy and the chemicals used in this part of the process.

The main phases defined as “wet” leather processing or pre-tanning are:

- Soaking, liming, unhairing and scudding – operations to be carried out in revolving drums

- Liming and splitting (when possible) – operations to be carried out with special machines

- Tanning (bating, deliming and pickling ) – operations to be carried out in drums

- Re-tanning, dyeing and greasing – operations to be carried out in drums

These are the steps necessary to give the hide some of its final characteristics such as softness, mechanical resistance and colour. Let’s now take a closer look at how the tanning, re-tanning and dyeing process takes place.

Tanning

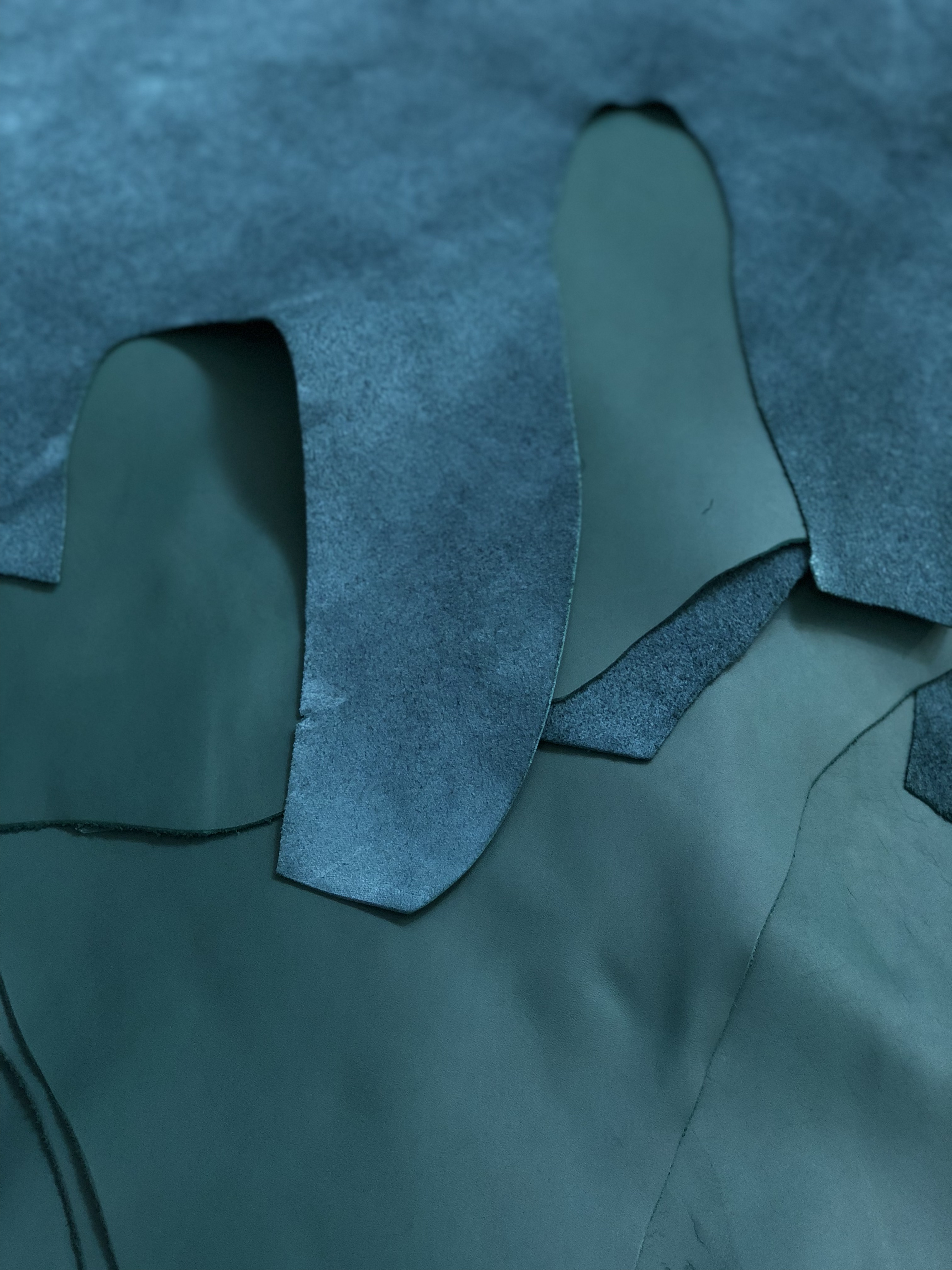

The tanning is the process performed in a drum which makes the skin rot-proof, wear-resistant, water proof and permeable to air and steam. This last feature makes the leather breathable thanks to its porosity, making it a hygienic and precious material. The result of this process is wet skins with a light blue color called Wet Blue.

Once obtained the Wet Blue , an experienced tanner assesses one by one, the skins obtained from tanning. These are divided according to customer demand. The selection then follows precise logics, depending on the size of the surface that has been cut, the type of article and the size of the leather. The Wet Blue must never dry out, it must remain moist throughout the process (as the name suggests) in order to move successfully to the next steps.

Re-tanning

Wet Blue skins are then re-tanned inside special drums. This part of the process gives the leather more mechanical resistance and uniformity, but also softness, elasticity and lightness. In practice, re-tanning is essential in determining the high quality of the skin and some of its final characteristics

Dyeing

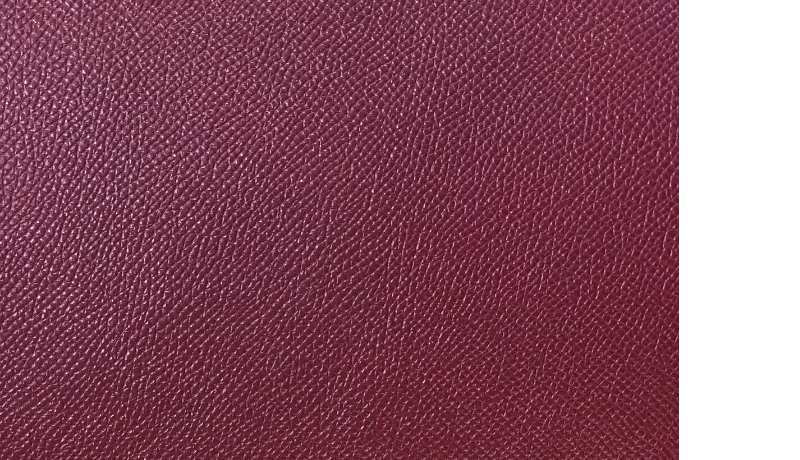

After tanning and re-tanning, the wet phase also includes the dyeing process. This phase is carried out by placing the hides into drums, inside high-temperature water solutions enriched with water-soluble dyes. By doing so, the dye can be absorbed not only on the surface but throughout the thickness of the skin, giving uniformity to the colour.

Once tanned, re-tanned, dyed and finally dried, the hides are ready to face the last part of the process: the “dry” phase of the finishing process, where are to be defined precisely all the technical, organoleptic and product characteristics of the leather.